Inconel Alloy

Product name:

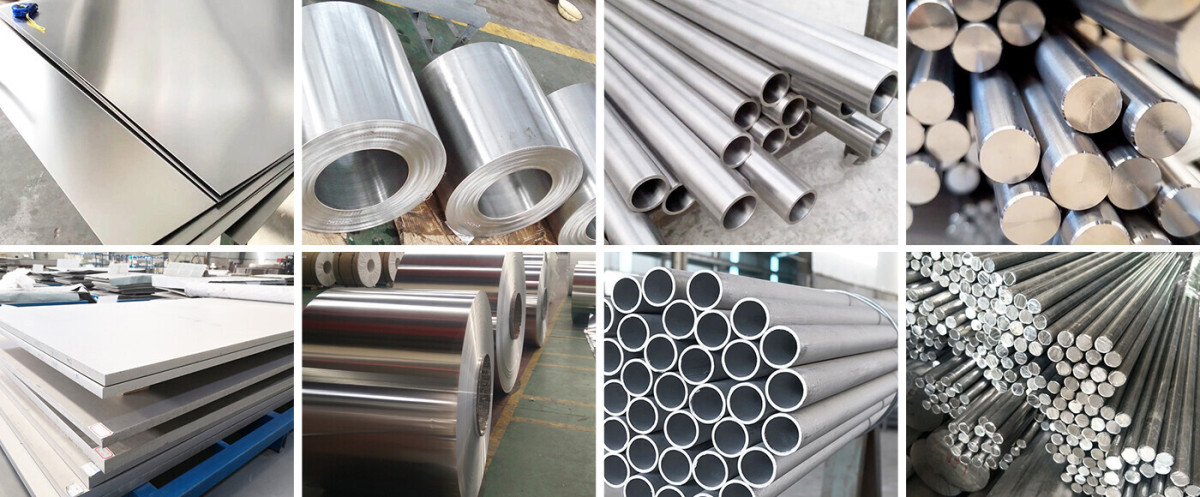

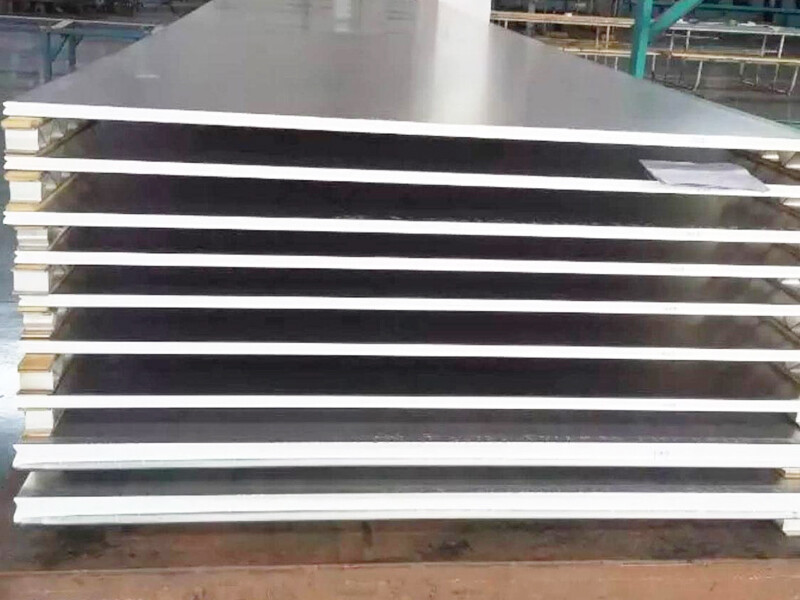

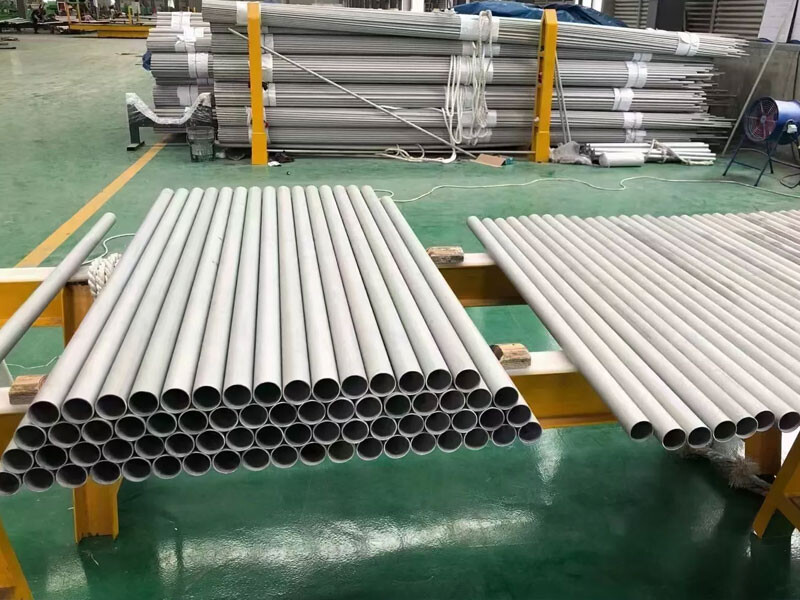

Inconel601/Inconel600 Alloy Sheet/Plate

INCONEL is an austenitic superheat resistant alloy with nickel as the main component. From the molybdenum, niobium solid solution that contains in ni chromium alloy to strengthen the effect, in the range of low temperature to 1093℃, with ultra high strength, special anti-fatigue characteristics, is widely used in aviation business, suitable for the production of low load under 1100℃ anti-oxidation parts.

INFORMATION PRODUCTS

Online Consulting

Other popular products

Feel free to contact us

You can consult us at any time if you have any questions. You can email or call us at any time, and we will reply to you as soon as we receive your information.

Siéntase libre de contactar con nosotros

Puedes consultarnos en cualquier momento si tienes alguna duda. Puede enviarnos un correo electrónico o llamarnos en cualquier momento y le responderemos tan pronto como recibamos su información.